industry

Best Practices for Energy-Efficient Rotary Screw Compressor Maintenance

Improving energy efficiency in rotary screw compressor maintenance not only saves money but also extends the life of your equipment. By following energy-saving practices, you can optimize performance and reduce environmental impact. This guide covers the best rotary screw compressor energy saving tips every facility should follow.

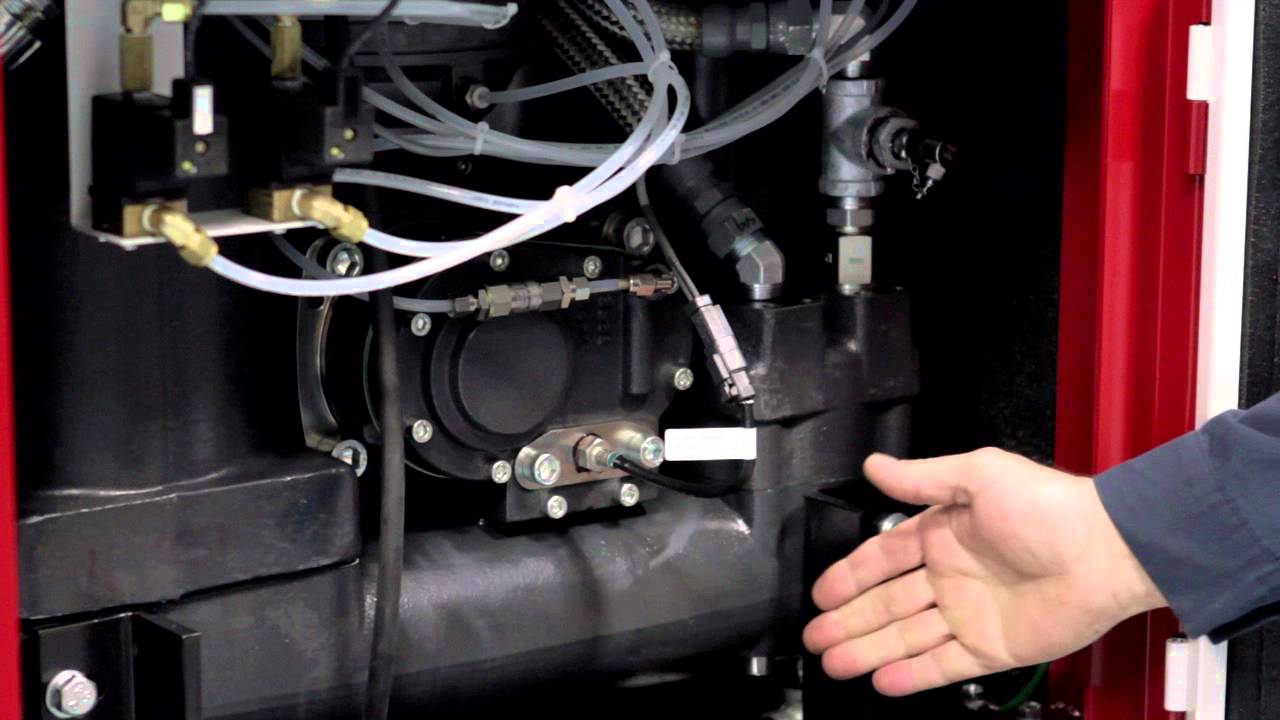

1. Conduct Regular Maintenance

Routine inspections help identify worn parts, dirty filters, or low oil levels—all of which increase energy usage. Schedule preventive maintenance monthly to avoid unnecessary power consumption.

2. Use the Right Lubricants

High-quality, OEM-recommended lubricants reduce internal friction and overheating. This allows the compressor to run more efficiently and with less effort.

3. Fix Air Leaks Promptly

Even minor leaks can cause your compressor to work harder to maintain pressure. Conduct leak audits regularly and seal any leaks to cut energy waste.

4. Optimize Air Pressure Settings

Set the compressor to the lowest acceptable pressure. Over-pressurizing wastes energy and accelerates wear.

5. Ensure Proper Ventilation

Well-ventilated spaces keep the system cool, which reduces strain and improves performance. Install cooling fans if necessary.

6. Upgrade to Variable Speed Drives (VSD)

VSD technology allows compressors to adjust output based on demand, reducing energy consumption significantly.

By applying these rotary screw compressor energy saving tips, businesses can reduce operating costs and boost system reliability.

For expert maintenance or a custom efficiency plan, explore our

Rotary Screw Compressor Maintenance services. Visit our

Screw Air Compressor Maintenance page or

Contact Us for personalized advice.